Implemented by the Cagayan State University (CSU), the pilot-testing of three locally developed peanut-postharvest mechanization and bulk storage technologies was finally completed in selected provinces in Regions I, VI, and X.

This was through the funding support of the Philippine Council for Agriculture, Aquatic and Natural Resources Research and Development of the Department of Science and Technology (DOST-PCAARRD).

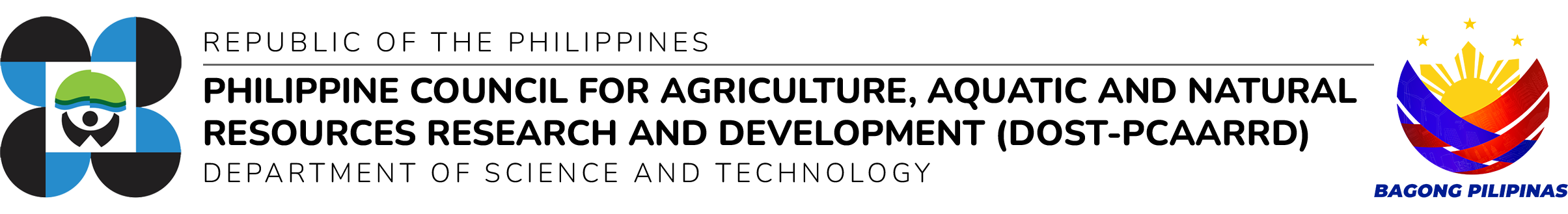

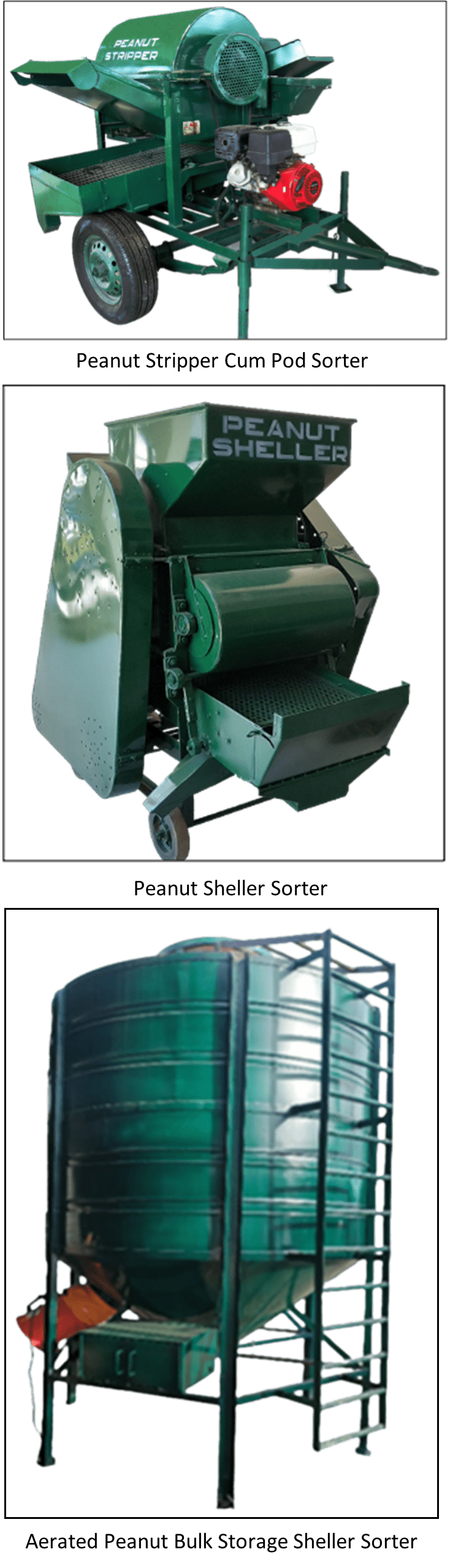

Dr. Jose D. Guzman, CSU project leader reported that the peanut stripper-sorter, sheller-sorter, and the automated aerated bulk storage system performed well in Vintar, Ilocos Norte; San Joaquin, Iloilo, and Claveria, Misamis Oriental. Findings show the following features of the machines:

Peanut stripper cum pod sorter separates the pods from the vines of the peanut plants; has a stripping capacity of 116 kg/hour, and stripping efficiency of 93%; helps reduce labor cost by up to 70%;

Peanut sheller-sorter breaks and separates the kernels from the pod through impact action and cleans peanut kernels through aspiration; had surpassed the Philippine Agricultural Engineering Standards (PAES); had 99% shelling efficiency, 98% shelling recovery, and 144 kg/hr shelling capacity.

Aerated peanut bulk storage system stores in-shelled peanuts; equipped with a system that monitors the temperature and humidity inside and outside the storage bin that assures avoidance of 5-10% losses and supply of quality unshelled peanuts.

The project has an existing patent application for these three machines. It has trained farmers and potential users on the maintenance and basic troubleshooting of the machines.