Industry Picture

Industry performance. Goat production in the Philippines is currently a sunrise industry that is 99% backyard (PSA 2016). Commercial investors are however increasing since the turn of the millennium. It stands at a meager 3.71M head in 2016. This small population base is traceable to two basic factors --- high slaughter rate and low productivity. Low productivity stems from lack of knowledge on improved management practices and lack of access to quality breeders. This leads to the dam having long production cycles of more than 9 months with conception rate as low at 75%; kids on the other hand have high preweaning mortality rate (25%). Growth is slow and weight averages only 15kg at market age.

Demand-supply situation. Despite the low production level, demand for goat meat is robust, as goats slaughtered has always been higher than kids born alive. At present, farm gate and carcass prices of goat are high, even higher than prices of beef. Max’s Fried Chicken and Fresh Options have tried for years to have chevon in their menus but supply until now remains limited. Even Bangladesh has asked the Federation of Goat and Sheep Producers and Associations of the Philippines, Inc. (FGASPAPI) to supply them with 200hd of goats twice a month but the deal did not push thru because there is not enough supply (SR Roadmap, 2016).

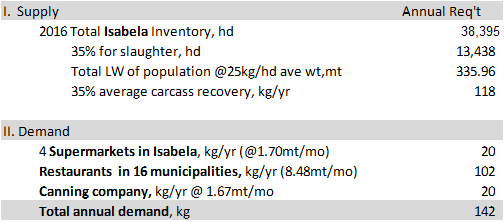

Across the country this scenario is echoed. In Isabela alone, annual demand is estimated at 142mt (Table 1): 20mt for just 4 big supermarkets in Ilagan, Cauayan, Roxas, and Santiago City; 102mt for kambingan restaurants in at least 16 municipalities; and 20mt for a processing company to be used in chevon canning. This demand however cannot be met, as this would mean slaughtering on average 1,355 25-kg goats per month or 16,262hd/yr. In 2016, Isabela only had 13,438hd goats for slaughter (PSA, 2017) capable of giving only 118mt of meat.

Table 1. Chevon supply and demand in Isabela, Cagayan Valley, 2016

Nutraceutical importance. This means that currently there is much potential in goat production as supply cannot yet meet demand. As consumer preferences shift to healthy options worldwide, demand for goat therefore increases, as its meat is known to be lower in saturated fat than chicken, pork and beef and low in cholesterol (Table 2). It also requires lower investment with a high rate of return. There is also high promise in producing authentic halal goat, a niche that Muslim Mindanao can embark on, considering the continuous high demand from our Muslim brothers within and outside the country.

Table 2. Nutrient composition of goat and other types of meat 1, 2

Nutrient | Goat | Chicken | Beef | Pork | Lamb |

Calories | 122 | 162 | 179 | 180 | 175 |

Fat (g) | 2.6 | 6.3 | 7.9 | 8.2 | 8.1 |

Saturated Fat (g) | 0.79 | 1.7 | 3.0 | 2.9 | 2.9 |

Protein (g) | 23 | 25 | 25 | 25 | 24 |

Cholesterol (mg) | 63.8 | 76.0 | 73.1 | 73.1 | 78.2 |

Iron (mg) | 3.2 | 1.5 | 2.9 | 2.7 | 1.4 |

Essential amino acids | Essential amino acid composition of goat meat closely resembles that of beef and lamb. | ||||

1 Per 3 oz. of cooked meat

2 USDA Nutrient Database for Standard Reference, Release 14 (2001)

The National S&T Initiatives

Objectives. The national goat S&T initiatives were laid down specifically to address these gaps in a holistic way. From 2008 to 2016, about 7 programs on goat have been funded by PCAARRD. All these were focused on accelerating enhancements in goat productivity by:

• Improving conception rate of does from 75% to 90% by 2020;

• Shortening kidding interval from 9 to 8 mos. (increased kidding index from 1.35 to 1.52kidding/yr);

• Decreasing preweaning mortalities from 25% to 5% by 2020;

• Increasing slaughter weight from 15kg to 30kg by 2020;

• Establishing standards for goat slaughtering and cutting by 2015;

• Developing standards for halal goat quality assurance by 2018; and

• Making available authentic halal goats in Muslim Mindanao by 2019;

As of December 2016, much has been reaped from the more than P100,000,000 investments of DOST-PCAARRD.

R&D Accomplishments

Improving management practices. To improve goat productivity and enhance goat-based enterprises, science-based interventions on feeding, breeding, health, and farm recording were introduced. Three modalities were developed and used to bring these technologies to geographically dispersed raisers. These were the:

• Farmer Livestock School on Goat Enterprise Management (FLS-GEM);

• Online courses on goat; and

• AI delivery system.

Initially, the existing Farmer Livestock School on Integrated Goat Management was upgraded to the FLS on Goat Enterprise Management (FLS-GEM). This is an adult-focused modality that was first developed by PCAARRD in 2000 but upgraded in 2013. It focuses not only on the technologies of raising goats but also on building enterprises (Alo et al. 2014). It is the modality of choice by the industry as it ensured simultaneous dissemination of a uniform set of goat-based technologies and enterprises to a wider geographical setting at a faster rate.

Initially, the existing Farmer Livestock School on Integrated Goat Management was upgraded to the FLS on Goat Enterprise Management (FLS-GEM). This is an adult-focused modality that was first developed by PCAARRD in 2000 but upgraded in 2013. It focuses not only on the technologies of raising goats but also on building enterprises (Alo et al. 2014). It is the modality of choice by the industry as it ensured simultaneous dissemination of a uniform set of goat-based technologies and enterprises to a wider geographical setting at a faster rate.

As of September 2016, more than 4000 goat farmers have graduated from the 6-month FLS-GEM and more than 300 facilitators trained on FLS-GEM implementation.

Seeing the merits of the modality, the industry embraced it as the national training modality for goat production and made attendance to it a requirement for farmers before receiving any dispersed animal from government. This was contained in a board resolution passed in August 2014 by the FGASPAPI. It was likewise adopted by the Dept. of Agriculture as the common training modality for the whole country for goat production and is manifested in the National Small Ruminant Roadmap of DA.

As to the delivery system for Artificial Insemination (AI), it has already been incorporated into the Unified National AI Program of DA, which formerly caters only to cattle and carabao. Incentive to goat AI providers as well as support for hormone, LN2 gas and biologics from DA are now included.

The Program has also developed 9 e-learning courses on goat, which serves as the online version of the FLS. As of December 2016, more than 1700 extension workers, farmers, businessmen, and OFWs have graduated from these courses, which are lodged at www.e-extension.gov.ph through the collaboration with the DA-Agricultural Training Institute. These courses are as follows:

• Course 1. Establishing feed resources for your goats (developed 2008; 767 graduates to date)

• Course 2. Starting a slaughter goat enterprise (developed 2008; 387 grads)

• Course 3. Technological alternatives to traditional breeding management (developed 2013; 156 grads)

• Course 4. Alternatives to traditional feeding management (developed 2013; 234 grads)

• Course 5. Alternatives to traditional herd health management (developed 2015; 64 grads)

• Course 6. Alternatives to Traditional Goat husbandry management (developed 2015)

• Course 7. AI at your cervix: Goat AI for raisers (developed 2016; 56 grads)

• Course 8. AI at your cervix: basic course for inseminators (developed 2016; 9 grads)

• Course 9. Meatylicious meeh: slaughtering and cutting standards for goats (developed 2016; 46 grads)

Hence, as of December 2016, more than 4000 goat farming households have been empowered on goat enterprise management thru FLS and online courses and several enterprises (goat breeding; buck-for-hire; marketing of forages; processing of manure; AI service provision; etc) have been introduced for the rural stakeholders to increase their income.

Improving conception rate. Since high mortalities of kids have been traced to the poor nutritional plane and disorders of the does before, during and after kidding, interventions were first done with the doe.

From 2013-2016, different variants of flush feed for the does in the form of soilage (fresh forage salad), leaf meals, and pelletized blended rations (PBR) were developed. These feeds not only improved body condition of the doe prior to breeding, but they also stimulated ovulation, improved conception rates and increased litter size.

To further increase conception rates, an herbal dewormer from Makahiya-Caimito-Makabuhay, was developed. This is comparable to the commercial Ivermectin in efficacy but cheaper. This dewormer addresses the current resistance of goat worms to commercial dewormers. Specifically, the project has formulated two variants of the dewormer---one in capsule form and the other in suspension. Both are currently awaiting commercialization by drug manufacturers.

Improved feeding & health management practices were promoted among farmer enrollees of the Farmer Livestock School. Because of these interventions, coupled with the awareness of raisers on the other aspects of integrated goat management, many does were properly readied for breeding, kidding and lactation. As a consequence conception rate increased from 75% to 87% and more kids were born alive.

Improved feeding & health management practices were promoted among farmer enrollees of the Farmer Livestock School. Because of these interventions, coupled with the awareness of raisers on the other aspects of integrated goat management, many does were properly readied for breeding, kidding and lactation. As a consequence conception rate increased from 75% to 87% and more kids were born alive.

Partnering with PCAARRD in this endeavor were DMMMSU; ISU; SRC-CLSU; DA-RFO8; SKSU; Ngilay Farm in Tambler, Gen. Santos City; and CMU. As these research institutions and private farms pursued seed production to this day, forages can thus be distributed to more farmers in the future and better productivity is expected from goats.

Improving preweaning survival. Aside from conditioning the doe prior to kidding, giving of preweaner supplements was also seen to help increase kid survival.

To date, a cocowater-based drench formulation has been developed and was found to prevent decline in blood glucose in kids, hence can support positive weight gains in kids especially in the first month of life while lessening the burden of suckling. This drench therefore is beneficial for orphaned/abandoned kids or those whose dams have mastitis and cannot provide milk. This product is now ready to be offered for commercialization to interested clients.

Three creep feeds have also been formulated to help bridge the gap from liquid (milk) to solid (forage) feeding. These transition feeds used highly digestible energy and protein sources with mineral supplements.

Training raisers on proper health management of kids also helped a lot in controlling kid mortality. Adoption of proper housing design and confinement, late grazing, and strategic deworming along with giving of clean feeds all helped to curb preweaning mortality from 25% at project start to 4.49% as of December 2016.

Decreasing kidding intervals (KI). The long production cycle of does was observed to be mainly due to seasonality of breeding and lack of access of does to bucks. To stimulate estrus and induce off-season breeding among does, three non-invasive heat induction techniques (NIHIT) have been tested and found to effectively aid in bringing does to heat without using chemicals. These are (1) manipulation of darkness inside pen to increase to 14hrs the “night effect” that stimulates heat among does; (2) keeping a buck nearby for 12hrs or less to induce heat thru the olfactory nerves (smell); (3) keeping 3-5 does together in a pen, as estrus of one causes others to come to heat too.

This also helped decrease KI by 11% (9mos to 8 mos) and increase kidding index from 1.35 to 1.52 kiddings per year. As of October 2015, the semen-extender mixture, SemEx, has also been improved thru the addition of antioxidants, use of a different cryoprotectant and by defining the role of sugar in the extender formulation. This mixture is a product added to goat semen to increase the amount of fluid for insemination while improving livability of sperm cells.

An improved cryobiology protocol to extend the life of stored semen has also been developed and is being using with the AI technology.

Increasing slaughter weight (SW). Another reason for the introduction of the AI delivery system was to upgrade the genetic makeup of slaughter goats in the countryside without the farmers maintaining a buck. At the moment, birth weights of kids have increased from 1.50 kg to 2.25 kg and the current average slaughter weight of goats that were produced from AI is 27kg. This is over the target weight of 24kg and this may be due to the fact that their grand parental lines have been the products of previous projects, where stock upgrading has been done. On the other hand, current data on slaughter weight of offspring from natural breeding also increased from 15kg to 23.25kg. The difference in SW between those from AI and natural means can be attributed to the kind of bucks available in the countryside. Semen used in AI were from genetically superior bucks available in breeding stations while those used in natural breeding were mostly from upgraded bucks present in individual farms. Just the same, an improvement was seen in SW, although a faster rate of increase can be had thru AI.

Preparing the industry for the influx of chevon. Optimistic that the industry will attain an increase in goat population and volume over time, the project led by ISU collaborated with the Bureau of Agriculture and Fisheries Product Standards of DA, FGASPAPI and NMIS to establish the Philippine National Standards on the Code of Practice for Hygienic Goat Slaughtering and the PNS on the Chevon Cuts. These standards were released by DA-BAPS in 2015. With these standards the industry can expect better slaughtering and cuts and can therefore institute the right pricing scheme.

Likewise to add value to the products and ensure that nothing goes to waste after slaughtering, chevon products from bones and meat trimmings were developed by the Program. As of December 2015, 9 chevon-based food products (diff variants of chevon mixes, ready to eat chevon in pouches; bulgogi; kambing satay; bouillon) have been developed and applied for patent.

Also a bouillon dehydrator has been fabricated. These products are currently in different stages of commercialization. In 2015, three canned products have been commercialized with AgricComponent Corporation, a commercial establishment that processes and cans chevon in Isabela. These are the canned adobo kambing, kambing kilawin and kalderetang kambing.

Halal goat initiatives. The potential of producing authentic halal goat is a niche that SUCs in Region 12 has embarked on. As of October 2015, the protocols on halal goat production has been developed and validated by the Muslim communities in Mindanao. In fact they have been promoted in many forums and scientific gatherings. Likewise, a laboratory-based haram detection protocol has been established and a haram test kit is currently being developed (for completion in 2018). Three halal processed chevon products (jerky, sweet-cured and corned or shredded) have also been formulated, tested, and promoted and will soon be commercialized.

To promote these protocols and products, a Farmer Livestock School on Halal Goat Enterprise Management is being developed using the original FLS-GEM as take-off point. This is expected to be pilot-tested in Region 12 and ARMM this 2017.

Impact on Goat Inventory

As can be noted in the PSA survey on goat inventory of 2016, there was an increase in goat population from 3.6M in 2013 (before the projects started) to 3.7M in 2016. Worth noting also is that Regions 1,3 10 and 12, the regions that were reached by the FLS-GEM significantly eased their way to the top 10 of the PSA ranking. Regions 1 and 3, where most of the FLS were implemented, moved up from ranks 3 and 5 to ranks 1 and 3; while Regions 12 and 10, which were not prominent in the past got ranks 8 and 9 respectively in 2016. The FLS initiatives is definitely not the only factor, but considering that goat mortalities in these regions decreased is enough reason to suspect that FLS had a lot to do with this resultant ranking.

It was also obvious that not only did the goat population increase but livelihoods were created in the countryside, as people at the farms were empowered with the right technologies and enterprises thru the FLS-GEM. True enough, the lowly goat is one sure bet in building rural assets, a real “SAGOaT sa kahirapan”.